REPREX focus on the recyclability of plastic materials for 3D printing production and develop the circular economy concept around it for an industry provider of orthopaedics’ product.

Recycling of the materials is only one step of the circular economy. The cost-effective aspects must be clearly considered, or users will continue with their traditional virgin materials. Costs of recycling plastics can vary widely depending on several factors, including the type of plastic, the recycling process used, local recycling infrastructure, and market condition. The mains cost in recycling of plastic are typically the collection and the sorting of them (about 75%) and added to possible contamination, such as non-recyclable items mixed in with plastics, it can increase processing costs and reduce the value of recycled materials.

In that perspective, REPREX want to use a close loop approach, and in that matter the orthopaedic market is an interesting candidate to create a circular economy business because:

- Products are patient tailored and cannot be reused.

- Products are used for limited time.

- Orthopaedic control the treatment´s duration and are in contact with the product to collect it.

- Product contamination is limited due to the type of users and utilisation.

- Orthopaedics have a stock of old parts. (PP, TPU, etc)

REPREX activities will be:

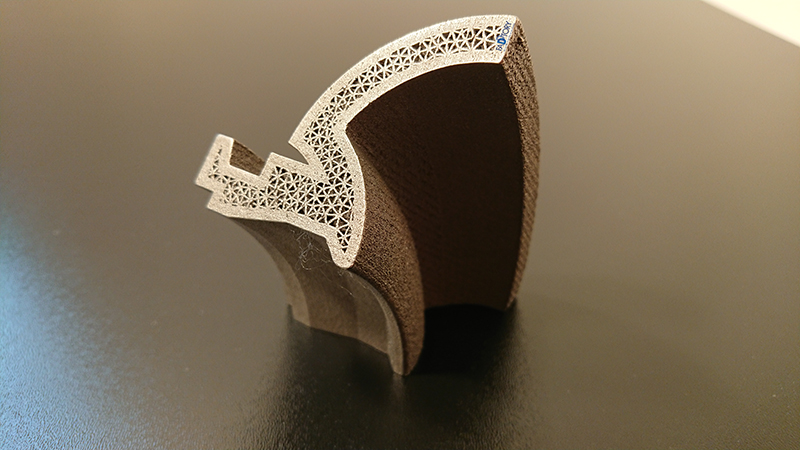

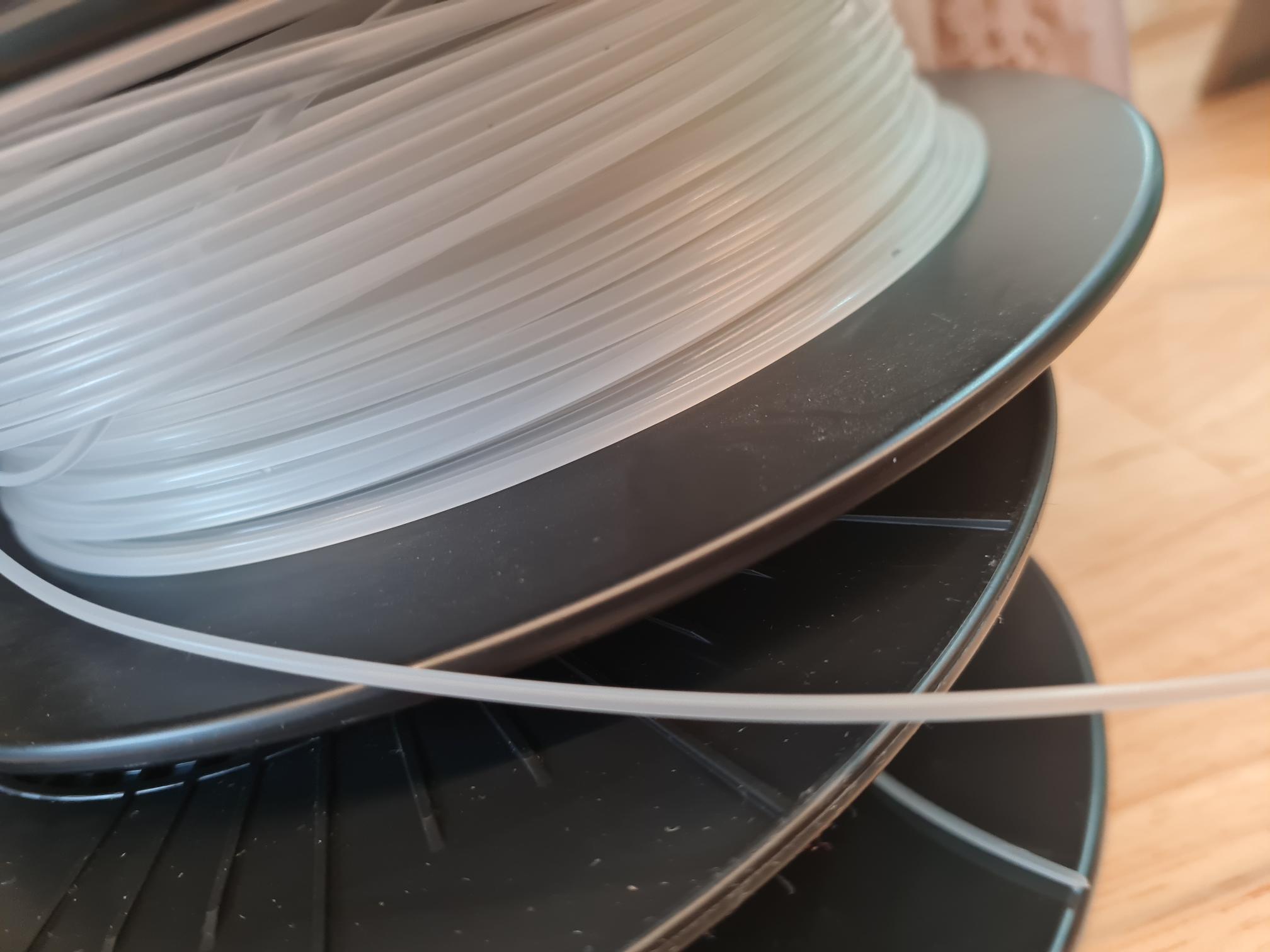

Recycling of plastics: Each of the plastics will be recycled from materials from 3Dprinting (supports of parts and old parts) and some from traditional production (PP materials). The aim will be to granulate, remove and control humidity in the materials before producing filament for Fuse Deposition Modelling (FDM) printer.

o Recycling of the PP from 3D printing.

o Recycling of TPU from 3D printing.

o Recycling of PP from traditional orthopaedics parts.

[video width="764" height="472" mp4="https://faddtory.com/wp-content/uploads/2024/01/20240108_114822-2.mp4"][/video]